Pewaukee Wastewater Pretreatment System

- Location: Pewaukee, Wisconsin

- Contractor: Rozga Plumbing & Heating Corporation

- Size: 25,000-gallon two-compartment equalization tank

- 25,000-gallon sequencing batch reactor tank

- 18,000-gallon solids holding tank

- 3,000-gallon oil holding tank

- Three manholes

- Purpose: To provide a wastewater pretreatment system to handle 14,000 gallons of wastewater per day while reducing the BOD from thousands to under 250 mg/L & FOG from thousands to under 300 mg/L.

About this Project

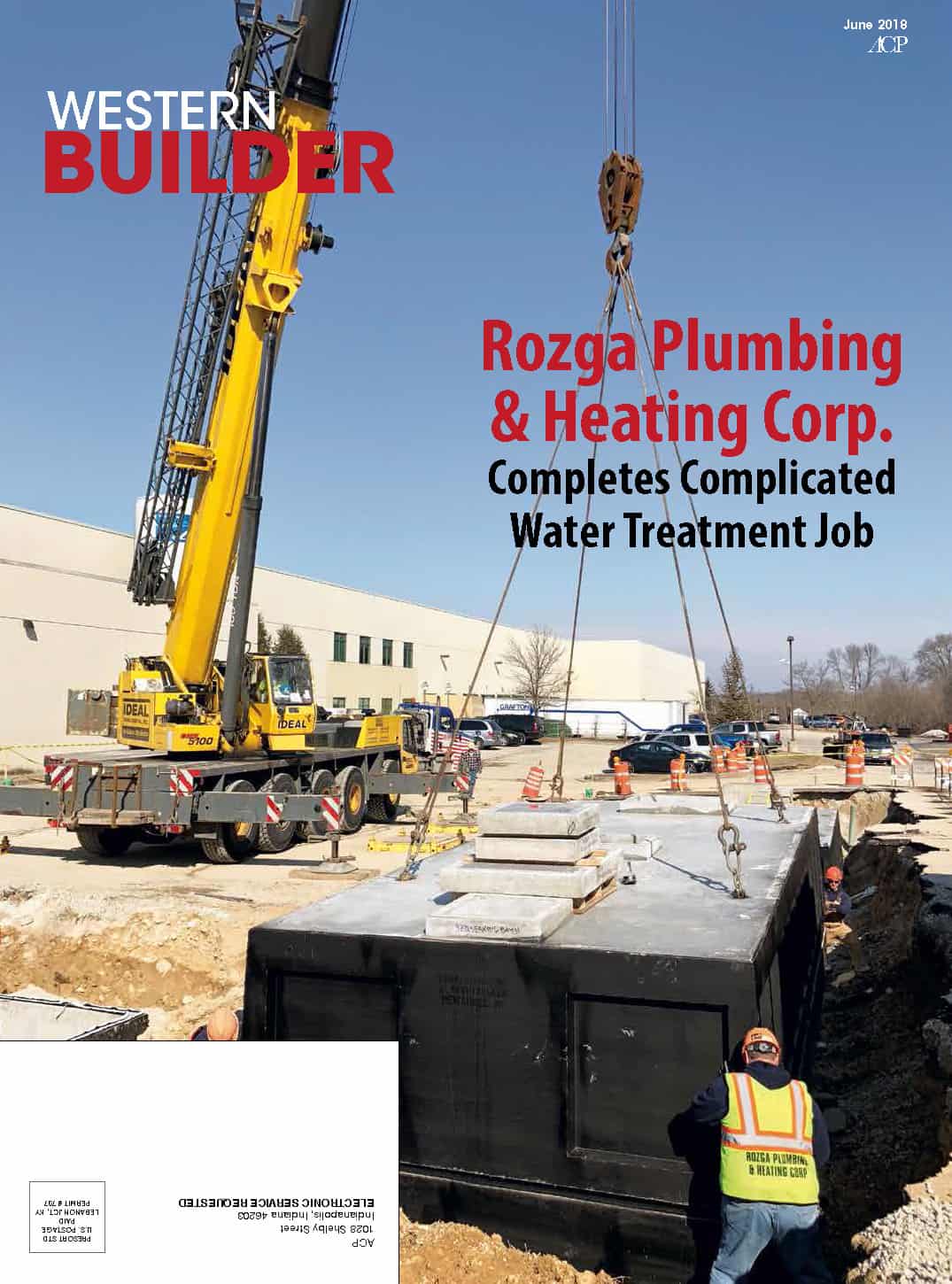

Western Builder, a magazine publication that has served Minnesota, North Dakota, South Dakota, Wisconsin, and Michigan’s Upper Peninsula since 1902, featured Wieser Concrete septic tanks on the front cover of their June issue. Rozga Plumbing & Heating Corporation, the main focus of the featured article, was asked to assist a customer who had extreme levels of biological oxygen demand (BOD) and fats, oils, grease (FOG) in their wastewater stream, which was also affecting a municipal system. The wastewater needed to be pretreated for the large food manufacturing plant in Pewaukee, Wisconsin, so Rozga worked with design engineers to design and install a wastewater pretreatment system. For the job, Wieser Concrete manufactured a 25,000-gallon two-compartment equalization tank, 25,000-gallon sequencing batch reactor tank, 18,000-gallon solids holding tank, 3,000-gallon oil holding tank, and three manholes. The project was designed to pretreat 14,000 gallons of wastewater per day while reducing the BOD from thousands to under 250 mg/L and FOG from thousands to under 300 mg/L.

Rozga Plumbing undertook this intricate job of custom designing a wastewater pretreatment plant through the design-build method and eliminated the customer’s constant fines with municipal compliance upon system startup. Todd Stair, Manager of Sewer and Water Division at Rozga, stated, “Wieser had the tanks and plans easily accessible on their website, so it was helpful up front in the design and bid process. We knew previously of Wieser quality and they were able to react quickly and worked closely with us on the job.” A 100-ton crane was used to install the tanks, while the food plant employees were still able to safely park and enter the facility. The entire project took only six weeks from start to finish, even though various challenges arose during the install. Challenges included the need to remove spoilage caused by unforgiving weather conditions, the high traffic area surrounding the job site, and general safety due to the close propinquity of the sustained food plant operation.