BioMicrobics FAST Systems

Innovative Ideas, Proven Products

With an immediate adoption of clean waste processing

technologies and development of better infrastructure to

protect water resources around the world, Bio-Microbics FAST®

technologies provide solutions for septic system rejuvenation

to small municipal wastewater treatment systems. We strive for

excellence in environmental protection and ensure that all our

water solutions – are made with the environment in mind.

- Microbial growth even in low/average/peak usage

- Increases settleabilty and eliminates sludge bulking

- Easy to maintain and extraordinarily reliable

- Exceeds minimum Nitrogen Reduction Standards

- Lessen the impact of harmful bacteria and viruses

- Takes all aspects of the treatment into consideration

Unobtrusive and dependable, the FAST® system handles

smaller, variable flows generated from onsite applications. The

clean effluent prevents biomat formation and leachfield clogging.

This septic technology is very compatible with shallow drip,

direct discharge, pressure distribution, spray irrigation, and

conventional leachfield.

The Bio-Microbics FAST® systems provide significantly improved

nitrification/denitrification performance over traditional systems

and exceeding typical effluent requirements for wastewater

recycling opportunities or reducing the size of the leach field

with less aesthetic disturbance of property value or system

components. Offering versatility and consistent high performance,

the FAST® are also a favorite on marine vessels and offshore

platforms of all types to produce high-quality effluent, specifically

designed for extreme environments.

Various Applications

Bio-Microbics FAST® wastewater treatment systems

provide alternative options for properties residing

outside the reach of municipal (public) treatment

plants. Engineered to fit most typical residential

and commercial applications, FAST® systems can

be used for new construction or retrofit in existing

tanks; including those in nitrogen sensitive areas

or limitations with distance to groundwater and/or

smaller dispersal field size requirements.

Scientifically-proven, advanced, self-contained

wastewater treatment systems, the process contains

no internal in-sewage moving parts. The Bio-

Microbics FAST® systems use only active naturally

occurring microorganisms to transform sewage

wastewater to be cleaner than natural surface fresh

water sources and protects family health, dwellings,

property values and freshwater sources.

How Does the FAST® System Work?

- Wastewater enters the treatment system

- Natural separation and settling processes occur in the

primary settling zone. - In the primary settling zone for most large residential and

commercial applications, a SaniTEE® device is used to

prevent large solids from entering the treatment zone. - A remote, above-ground blower introduces air (oxygen)

into the treatment module to facilitate a robust circulation of

wastewater through the media’s channeled flow path. - Bacteria in the aeration zone

become “fixed” or attached to the

stationary media. This is where the

abundant, diverse, self-regulating

population of microbes consistently

metabolize the incoming waste. - Clear, odorless, treated water is

ready for standard or innovative

dispersal.

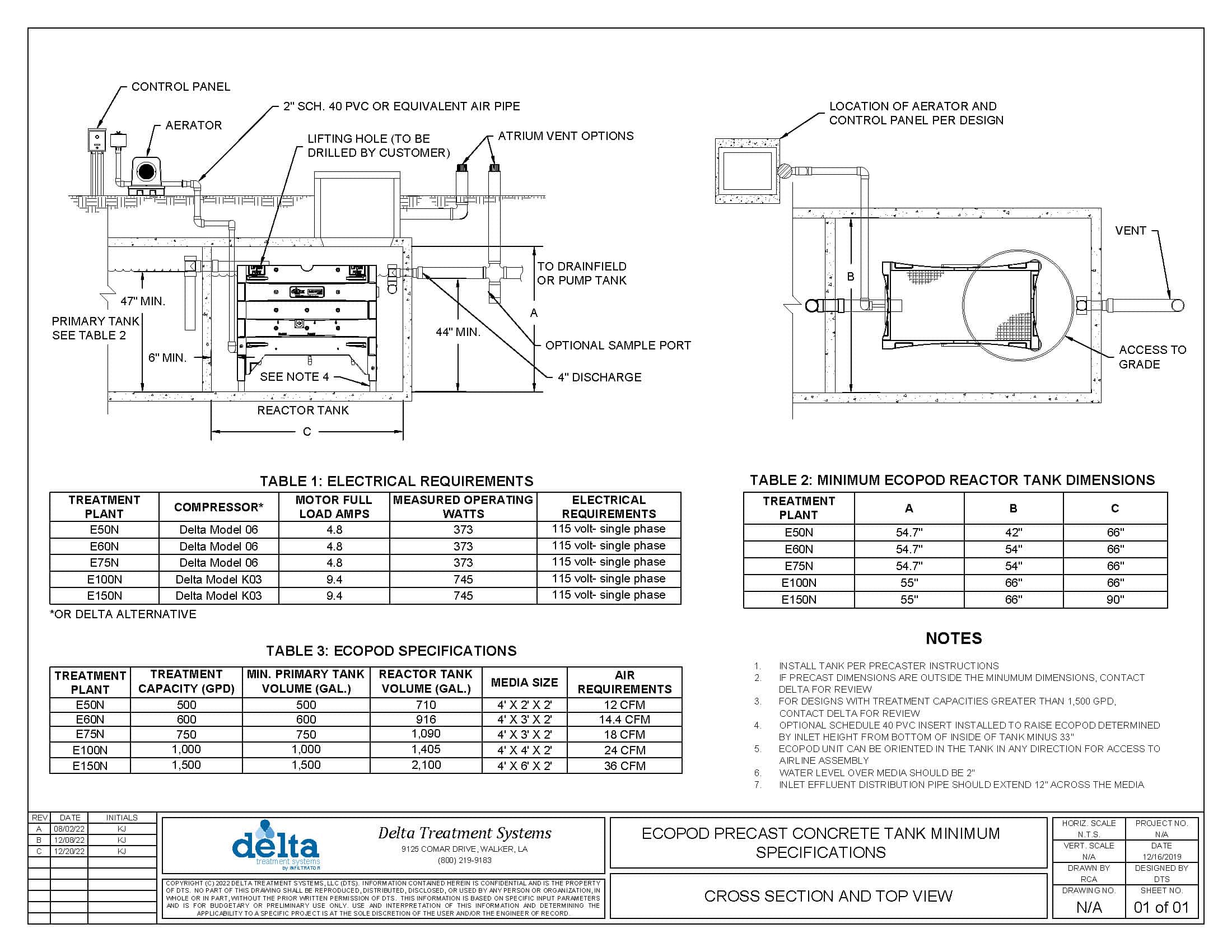

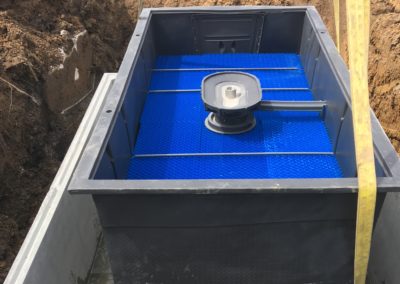

ECOPOD Systems

Features

- Oxygen is pumped into the system allowing the bacteria thrive and grow in much greater numbers than would occur naturally. This “overpopulation” of bacteria speeds the process of breaking down the sewage, making it safe for release into the environment.

- ECOPOD Units significantly reduce BOD, TSS, fecal coliform, and nutrients in the wastewater.

- Nitrification and denitrification occur in a single tank.

- Features a fixed film process which is characteristically stable, reliable, and sturdy. Fixed film is a preferred treatment process for onsite wastewater treatment systems.

Benefits

- The fixed film process provides a robust solution suitable for continuous or intermittent use

- Flexible and easy installations in tanks we supply or in 3rd party tanks

- Flexible design approach provides for plants to be installed below, above or at-grade

- With no mechanical parts internal to the unit, the ECOPOD is easy to maintain

- Designed specifically to minimize sludge production for fewer pump out cycles

- Low life cycle costs with minimal maintenance requirements

- Support through a dedicated team of engineers who act like an extension of your own team

- Wide range of solutions from 500 to 250,000 GPD

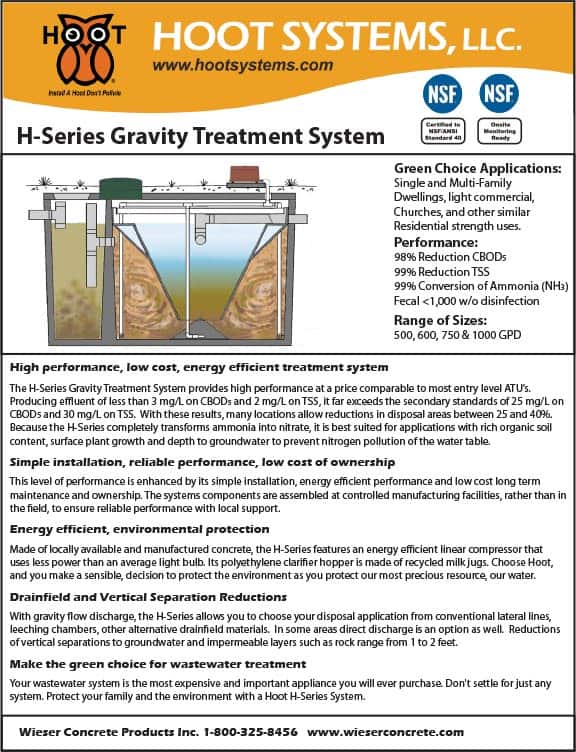

HOOT Systems

Wieser Concrete H-Series Gravity Treatment System

GREEN CHOICE APPLICATIONS

Single and Multi-Family Dwellings, light commercial, Churches, and other similar Residential strength uses.

PERFORMANCE

98% Reduction CBOD5

99% Reduction TSS

99% Conversion of Ammonia (NH3)

Fecal <1,000 w/o disinfection

RANGE OF SIZES

500, 600, 750 & 1000 GPD

HIGH PERFORMANCE, LOW COST, ENERGY EFFICIENT TREATMENT SYSTEM

The H-Series Gravity Treatment System provides high performance at a price comparable to most entry-level ATU’s. Producing effluent of less than 3 mg/L on CBOD5 and 2 mg/L on TSS, it far exceeds the secondary standards of 25 mg/L on CBOD5 and 30 mg/L on TSS. With these results, many locations allow reductions in disposal areas between 25 and 40%. Because the H-Series completely transforms ammonia into nitrate, it is best suited for applications with rich organic soil content, surface plant growth and depth to groundwater to prevent nitrogen pollution of the water table.

SIMPLE INSTALLATION, RELIABLE PERFORMANCE, LOW COST OF OWNERSHIP

This level of performance is enhanced by its simple installation, energy-efficient performance and low-cost long-term maintenance and ownership. The system’s components are assembled at controlled manufacturing facilities, rather than in the field, to ensure reliable performance with local support.

ENERGY EFFICIENT, ENVIRONMENTAL PROTECTION

Made of locally available and manufactured concrete, the H-Series features an energy efficient linear compressor that uses less power than an average light bulb. Its polyethylene clarifier hopper is made of recycled milk jugs. Choose Hoot, and you make a sensible, decision to protect the environment as you protect our most precious resource, our water.

DRAINFIELD AND VERTICAL SEPARATION REDUCTIONS

With gravity flow discharge, the H-Series allows you to choose your disposal application from conventional lateral lines, leaching chambers, other alternative drainfield materials. In some areas, direct discharge is an option as well. Reductions of vertical separations to groundwater and impermeable layers such as rock range from 1 to 2 feet.

MAKE THE GREEN CHOICE FOR WASTEWATER TREATMENT

Your wastewater system is the most expensive and important appliance you will ever purchase. Don’t settle for just any system. Protect your family and the environment with a Hoot H-Series System.